The clean coal delusion

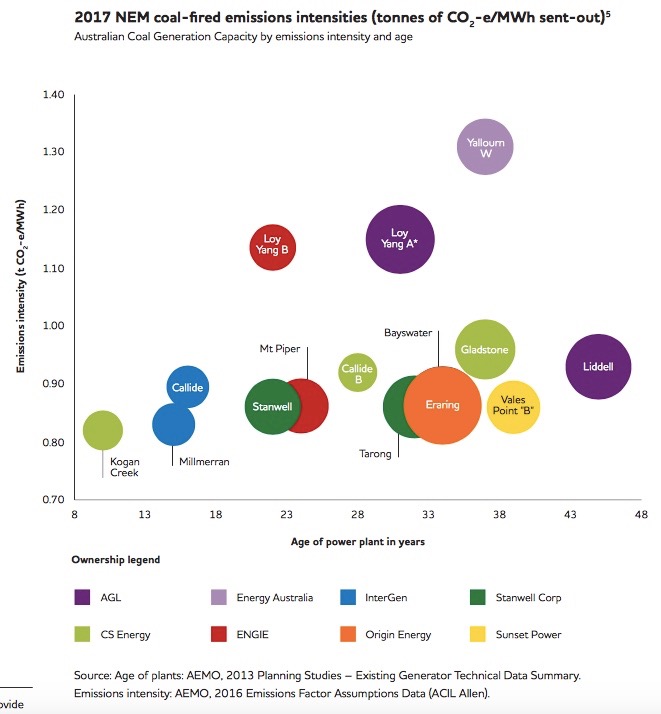

The graph below, extracted from Origin Energy's Sustainability Report 2017, shows very well that the idea of clean coal is delusional.

It shows the emissions intensity against the ages of all Australia's coal-fired power stations.

The upper three power stations in the graphic burn brown coal and are consequently dirtier than the others that all burn black coal.

|

Considering only the black-coal-fired power stations (the lower group), in the 35 years between the building of the Liddell and Kogan Creek power stations emissions intensity have improved from about 0.92 to 0.82 tonnes CO2/MWh; an improvement of only 11% in 35 years. Even supposing that that rate of improvement could be maintained, which is questionable, clean coal would be a very long time coming.

|

|

While there is no such thing as clean coal, cleaner, or greener, coal is possible

(This page uses several technical units. Energy units, definitions and conversions are available on an additional page. That page also gives figures for the amount of energy that can be obtained from a list of fuels.)In Australia at least, the operators of coal fired power stations have two unfair economic advantages over sustainable electricity:

1. They are able to dump their wastes into the atmosphere at no costs to themselves (see No level playing field and Fossil fuel electricity in perspective);

2. They are heavily subsidised by the government. (While sustainably generated electricity is sold at a higher price than fossil fuel generated electricity – and this is a form of subsidy – it does not receive the numerous hidden subsidies that fossil fuel power gets.)

Removing the subsidies and applying a

carbon tax

would 'level the playing field'. It would no longer be necessary to

sell sustainably generated power at a higher price than fossil fuel

generated power.

Acknowledgements

Frank Nizynski of the Australian Coal Association provided me with links to several useful sources.Rod Brunker of HRV Flinders (the operators of the Leigh Creek coal mine) provided me with a list of percentages of the major constituents of Leigh Creek coal.

The librarian (no name given) of the

Conservation Council of SA

also provided information.

|

|

|

Coal liquefaction

Coal liquefaction, the production of liquid petroleum fuels from solid coal, seems to be little discussed in Australia, at least up to the time of writing (June 2005). The process was developed in oil-hungry Germany in World War Two and later used in the economically embargoed apartheid South Africa.As petroleum becomes progressively more scarce and expensive the production of liquid fuels from coal will become steadily more economically attractive. It will be essential for the sustainability of the world environment that liquefaction of coal is combined with sequestration of the carbon dioxide produced in the process.

Carbon dioxide is produced as a by-product of the liquefaction process. It is again produced when the liquid fuel made from the coal is burned. So coal liquefaction is more bad news for greenhouse/climate change.

Wikipedia states that the break-even oil price where liquefaction of coal becomes viable is around US$25 to US$35/barrel. Elsewhere I have seen a price of US$60/barrel quoted. As I write (June 2005) the oil price is around US$55/barrel.

China, with its rapidly growing economy, heavy reliance on imported oil, and large reserves of coal, is the world leader in coal liquefaction technology. It is currently building a coal liquefaction plant with a capacity of a million tonnes per year. This is scheduled to come into production by 2007.

Ideally, coal liquefaction and carbon-containing liquid fuels should not be used because of the resulting greenhouse damage. However, if they must be used in the short-term, and that appears to me to be inevitable, society should be minimising the damage.

|

|

Coal gasification

Coal gasification is the production of combustible gases, such as carbon monoxide, hydrogen, and methane from coal. The gases produced are used as fuels, gaseous fuels being generally more convenient to use than solid coal.The coal is milled, dried and pulverized. It is then fed into a gasifier reactor, and at high pressure and temperature it is converted into synthesis gas ("syngas", mainly carbon monoxide and hydrogen).

The Queensland Government-owned Stanwell Corporation and Shell are working on

a study into the feasibility of "Integrated Gasification Combined Cycle" with

sequestration of the waste carbon dioxide. The study is due for completion

in October 2005.

Water in coal

Wet, or 'green' wood, doesn't burn well; the same applies to coal

Few people who have had any significant experience with wood fires, whether camp fires in the bush, or slow combustion fires in the home, would be unaware that green wood is greatly inferior as a fuel to dry wood. Green wood is wood straight from the tree. It contains a high proportion of water which must be boiled-off as the wood is burned. This reduces the value of the wood as a fuel in several ways:- You buy the wood by weight. If it is green then some of what you are buying is water;

- It adds 'dead weight'. When you carry or transport the wood you are transporting water that is of no value;

- A fire built of green or wet wood does not burn well;

- A fire built of green wood produces more smoke;

- Most importantly, a significant part of the energy of the burning wood is wasted in boiling-off the water.

Wet coal

Burning wet coal has much the same disadvantages as burning wet or green wood. And the energy loss is not only in the burning, transporting all that worse-than-useless water also has a cost. Coal can contain 30% or more water, that means that a thousand-tonne train load of coal could contain 300 tonnes or more of water. If it was possible to substantially reduce the water content of the coal at the mine a huge amount of energy would be saved and a huge amount of greenhouse gas would no longer have to be released into the atmosphere.|

|